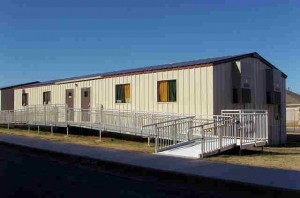

Aluminum access products are indispensable anywhere you need to provide safe passage for pedestrians from one point to another. They can provide safe, ADA-compliant access to site-built and modular buildings for people with mobility problems. Premanufactured metal ramps are also in demand on jobsites in the construction, aerospace, and automotive industry, and for applications in shale-oil and gas production.

REDD Team is the original access solutions company. We have the tools and knowledge to correctly assess and measure your property for aluminum ramps, and can help you with building codes and other local regulations that may apply to you. Whatever type of solution you need, we are confident that our team will meet your most rigorous requirements.

REDD Team is the original access solutions company. We have the tools and knowledge to correctly assess and measure your property for aluminum ramps, and can help you with building codes and other local regulations that may apply to you. Whatever type of solution you need, we are confident that our team will meet your most rigorous requirements.

Some advantages of REDD Team’s universal ramps include:

- Lightweight (30% of the weight of steel), but durable and extremely portable

- Manufactured from high-quality 6061-T6 tempered structural aluminum

- Smooth, continuous handrails

- Slip-in rails and legs for easy installation

- Not susceptible to rotting and splintering (like wood)

- Easy to keep clean and virtually maintenance-free

- Non-corrosive, non-combustible

- Engineered to withstand high winds

- Naturally attractive without further finishing

- Can be used without coatings or paint (Steel, which has to be painted, can be more expensive than aluminum for this reason.)

- Raised/abraded surfaces and tread patterns promote better water drainage and provide an excellent non-slip surface

- Can be dismantled, relocated and reassembled elsewhere

- Can be recycled, making them environmentally friendly

Available in standard and custom sizes

REDD Team’s prefabricated modular aluminum access ramps are available in standard 6’, 8’ and 10’ lengths. Custom lengths can be fabricated as requested. All ramp sections are designed for variable heights and slopes. Guardrails and handrails are designed to resist a single concentrated load of 200 pounds applied at any point and in any direction at the top of the guardrail or handrail and to transfer this load through the supports to the structure. Handrails are typically 34” or 38” tall with vertical pickets or two line handrails. Guardrails are designed so that a 4” sphere cannot pass through any opening.

Slip-resistant ramp surfaces

The walking surface of the ramp is continuous, without gaps, and consists of 1 ½ inch X 6 inch and/or 1 ½ inch X 8 inch self-mating aluminum deck with extruded slip resistant surface.

Maintenance free

Aluminum doesn’t rot, splinter or burn like wood. It doesn’t need paint or a coating to protect it, so there’s nothing to wear out or scratch off, requiring continual retreatment. Aluminum doesn’t rust. It’s ideal in moist, damp or abrasive environment where steel and other metals may rust and corrode. Your aluminum ramps will be virtually maintenance-free.

Made in America

REDD Team’s universal ramp system is made in the USA from raw material that contains approximately 25% post-consumer recycled aluminum. We recycle 100% of all of the aluminum scrap we generate onsite, and the products themselves can be completely recycled into new raw material. Wood and concrete ramps are expensive to remove and generally end up in a landfill, while aluminum ramps are long-lasting and can be easily disassembled, reassembled and/or reconfigured when you need to move them to a new location.

Aluminum is an outstanding metal for prefabricated walkways, stairways, platforms and ramps. Consider aluminum products from REDD Team for a durable, cost-effective way of providing temporary or permanent access to site-built or modular buildings and job sites.